Biosynthetic Technologies Delivers Innovations for a Sustainable Future

October 2, 2019

Biosynthetic® Technologies and DOD Case Study

November 26, 2019Oxidative stability measures the ability for oil to resist chemical degradation in the presence of oxygen. It is a critical property that correlates with the longevity of a lubricant. As oil oxidizes, acids are formed that lead to sludge formation. The average molecular weight of the oil also increases during oxidation resulting in a thicker more viscous oil.

Here at Biosynthetic® Technologies, we’re focused on offering products with both performance and environmental benefits. Therefore, understanding oxidative stability and how to best develop stable products is essential in our development efforts. Our fully saturated Estolide products like BT4, BT22, and BT75 are biodegradable and biobased yet have excellent oxidative stability and perform as well as other synthetic petroleum-based products.

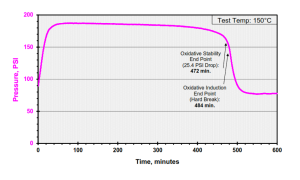

The Rotating Pressure Vessel Oxidation Test (RPVOT, ASTM D2272) is one of the primary oxidative stability test methods used in the lubricant industry. During the test, a sample is placed in a sealed vessel with 5 grams of water, a copper coil, and pressurized to 620 kPa (approximately 90 psi) with pure oxygen. The vessel is then placed in a hot oil bath heated to 150°C and rotated at 100 rpm. As the oil begins to oxidize, the oxygen used to pressurize the vessel is incorporated into the oil’s chemistry resulting in a loss in pressure inside the vessel. A pressure gauge monitors the pressure in the vessel over time until the system drops 175 kPa (approximately 25.4 psi) from the maximum pressure observed. At that point, the test is stopped, and the time is recorded and reported as the final result.

For mineral oils, a 25.4 psi drop in pressure corresponds closely with an induction-type period of rapid pressure drop referred to as the oxidative induction endpoint. This can be seen in Figure 1 for a polyalphaolefin (PAO) base oil.

Figure 1 – PAO (ISO VG 460 with 1% Antioxidant, 0.5% AO-130 and 0.5% AO-210), ASTM D2272

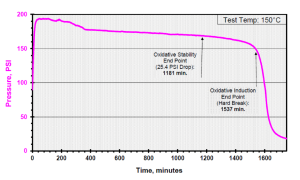

With saturated Estolides, however, the drop in pressure does not always correspond to the induction endpoint. Products like BT4, BT22, and BT75 have excellent oxidative stability even per the RPVOT test criteria but if the test is allowed to run to the oxidative induction endpoint there are still sometimes hundreds of minutes of life left in the biosynthetic oils as seen in Figure 2.

Figure 2 – BT75 (ISO VG 460 with 1% Antioxidant, 0.5% AO-130 and 0.5% AO-210), ASTM D2272

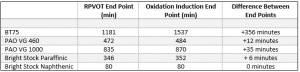

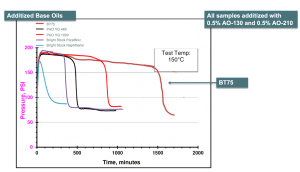

To get a perspective on why that matters, the results for BT75, PAO and Bright Stock are all shown together in Table 1 and Figure 3. BT75 does very well per the standard test compared to PAO and Bright Stock. However, the additional life in BT75 between the RPVOT endpoint and the oxidation induction endpoint is 356 minutes. That is longer than the entire life of either bright stock oil. Therefore, it’s important to run the test to the oxidation induction endpoint and ensure the full life of the oils is documented.

Table 1. RPVOT Results (Additized 0.5% AO-130, 0.5% AO-210) vs Oxidation Induction End Point

Figure 3 – BT75, PAO and Bright Stock with 1% Antioxidant (0.5% AO-130 and 0.5% AO-210)

In conclusion, while Biosynthetic Technologies has developed environmentally friendly products with excellent oxidative stability, the RPVOT test used to measure this parameter should be run to the oxidative induction endpoint to truly understand the life of the oil.